Introduction

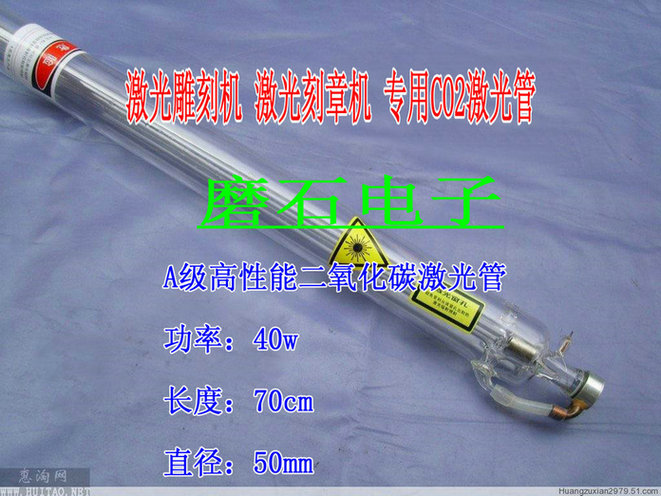

Laser engraving machine, laser seals machine for CO2 laser tubeBrand: chengdu tube (vertical pipe with Shanghai performance quite)

Power: 40 w

Length: 70 cm

Diameter: 50 mm

Double carton packaging filling sponge foam cushioning inside makes you buy goods to avoid damage, rupture.

A. Structure features:

This machine is mainly composed of hard glass, cavity, electrode of three parts.

1. Hard glass part; This part consists of GG17 material calcined into discharge tube, water-cooled, gas storage and muffler. Letter from CO2 laser is usually three layer casing structure. Most is the inside of the discharge tube, water net, is among the most outer layer is a gas storage, back to the trachea is used for connecting tube and the trachea.

2. Cavity part: this part consists of full mirror, and the output mirror. Of cavity mirror, an optical glass as substrate, the surface cross the gold film, gold film mirror reflectance near 10.6 um above 98%; The output of the resonator mirror can generally USES 10.6 um radiation transmission infrared germanium (Ge) as the base material, multilayer dielectric film, made of a cross on it.

3. The electrode parts: CO2 laser is generally USES the cold cathode, shape is cylindrical, cathode materials selected in life has a great influence on laser, the basic requirement of the cathode material is: low sputtering rate, small gas absorption rate, commonly used for nickel metal materials.

2. Method of use:

1. The first electrode wire connected, (+, -) extremely not wrong.

2. The cooling water pipe connected and the connection is to drink water from the cathode, the anode and satisfy the water into the out of principle, and the interface can't leak. Before use water storage containers must be enough water storage, water after the water cooling pipe must be the weather bubble can access (must see) before each use.

3. Maintenance, maintenance:

1. Every time before use must see whether water circulation normal, and no bubble.

2. Always see negative output mirror to see if there is dust and oily be soiled, if use fat-free cotton swab with ether, otherwise affect power and light spot. Lead to affect the service life of laser.

CO2 glass laser tube using the matters needing attention

There can't bubble. A cooling pipe, tube, and open the power. Requirements: cooling water using soft water (distilled water or pure water), and often pay attention to the temperature of the cooling water temperature should be controlled at 25 ℃ to 30 ℃ range, may not be too high or too low, especially in the summer, once found that the water temperature is too high, should be timely replacement of cooling water or stop to rest for a period of time: cooling water shall not be frozen in a cold district, especially the laser after downtime, may not keep cooling water storage in the laser tube, so as to avoid ice cooling water led to cracking. (note: use of alternating current (ac) user, cooling water tank must be earthed);

Second, laser tube of two supporting points in the laser tube length a quarter point, ensure the flow of cooling water in 2 l - 4 l/min; Otherwise the result is bad, will cause moding, light change several points to lower power; Cooling water nozzle in the tank must be flooded back cover, otherwise, every time shut laser tube cooling water filling dissatisfaction phenomenon when the phone is switched on.

Third, pay attention to protect the laser output window, avoid in the process of the work (including debugging in the process of the optical path) smoke splash to the output window surface and prevent the output window outside surface is pollution, power is reduced, then use absorbent cotton or silk cloth dips in anhydrous alcohol wipe gently output window outside surface;

Four, in the process of debugging, by adjusting the laser point or azimuth rotating laser, in order to achieve the best output effect, then fixed laser

5, please note: to avoid accumulation of dust near high voltage electrode, keep dry, high voltage side as much as possible to stay away from metal, to prevent high voltage spark discharge.

Six, laser in use process, can't have a scale in the cooling tube formation, so as not to block, the cooling water cooling effect. Once found, 20% of dilute hydrochloric acid cleaning, cooling pipe, remove scale.

Seven, laser glass, brittle. Install and use, avoid the local stress.

Eight, reasonable application of laser tube, laser energy saving, working current of the laser tube in 16 ma best point.

No, carved deep:

1, a light is not deep,

Check the laser tube bearing point is reasonable, strong light set is too small, light path is offset, the focal length is correct, ytterbium surface whether there is scratches and dirt, the flow of cooling water flow pressure is normal, more than a few no problem will examine, the laser tube light mouth inside the lenses have scratches and dirt, if is normal also so is the quality problem of the laser tube itself.

2, glow for a moment to moment is not deep,

This issue need to check the laser tube bearing point is reasonable, the water temperature is above 30 degrees, the lens is hot at work, the flow of cooling water flow pressure is not normal, whether water is clean, the above normal and then check the laser tube

2: light, high pressure and discharge check around the high pressure head dirt and moist, away from the machine metal parts is too close; Another is laser power supply high voltage connection whether fell off from the pedestal, high pressure connection whether to break and damage equipment. If the above normal so is the quality problem of the laser tube itself.

Three, laser tube broken, cracks, water head loss,

1. The temperature control in 25 ℃ to 30 ℃, cooling water shall not be frozen in a cold district, especially the laser after downtime, must not let the cooling water stored in the laser tube.

2. The light is under the control of water protection work; (will test the glow as the water on and off in light or light)

3. The water pipes have play phenomenon.

4. Whether the laser tube will have bubbles.

5. The water pressure water flow is normal; In the direction of flow is higher than that of low into.

6.1-5 normal if the laser tube is itself quality problems.

Contact phone: 18906358552 15063591363

QQ: 907777911, 582049764

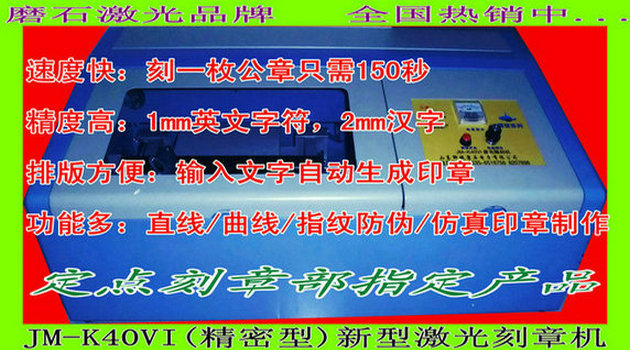

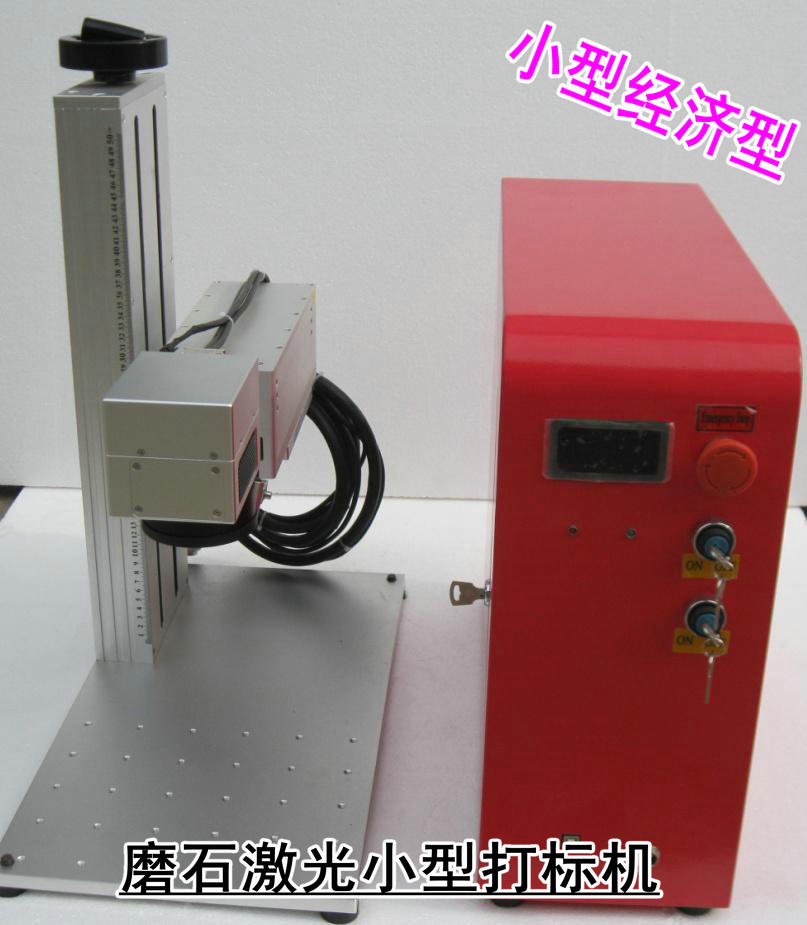

More Products